The only work around is to delete the flange feature from the timeline and recreate it.

Fusion 360 solid into sheet metal.

Sometimes these faces can get in the way of altering the design to your.

Let s show how to create sheet metal bends folds flange unfold flat pattern and more.

If sheet metal does not appear there enable parametric modeling mode by capturing design history.

Knowing we need an edge for our sheet metal our revolution stopped short of 360.

We re calling these sheet metal rules in fusion 360.

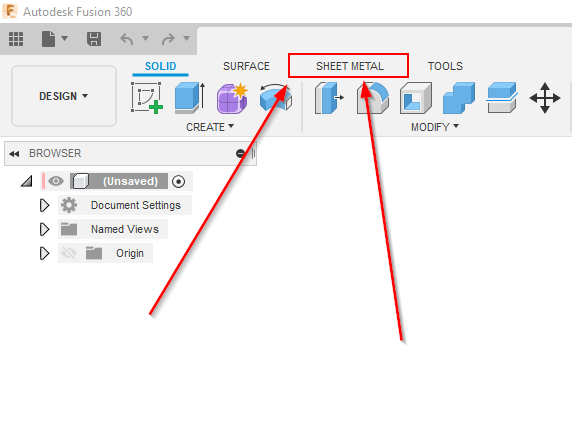

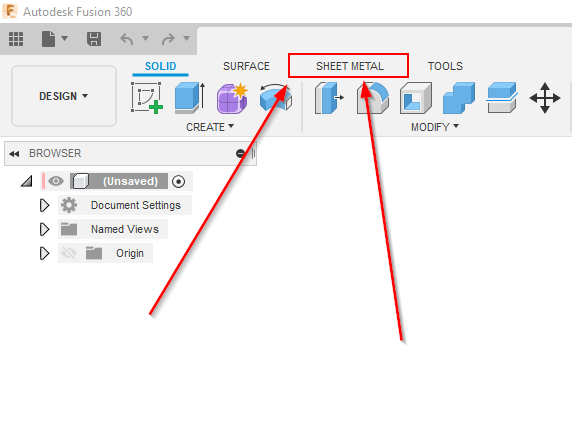

In the new ui the sheet metal environment is located in the tabs above the icons.

Right click on the top component of the design in the browser tree.

There is no option to access the sheet metal tab in the fusion 360 design toolbar.

The command is aware of what is being selected and will automatically switch to the right command.

Cleaning up faces of an stl file in fusion 360.

Thickness bend radius k factor relief shapes etc.

Non native parts are imported into fusion 360 as solids or surfaces and need to be converted into sheet metal components before flattening.

Since the flange tool defaults to the operation of creating a new body be careful.

Note that using the insert bend function requires a thin feature of uniform thickness to function.

With insert bends we can quickly convert our solid body to a sheet metal body that would have been fairly difficult and time consuming to create.

Fusion 360 has released the sheet metal modeling environment.

There are plenty.

A sheet metal part with a non f3d format for instance xt sat step was imported into fusion 360.

Properties are the root of how sheet metal designs behave.

How can it be flattened.

Our intention is to provide you a simple way to build your library by providing you with a handful of starter rules you can copy edit and save to your library.

Fusion 360 folds 5 sheet metal flange commands base edge contour miter and swept into one flange command.